WeldEye integration kit

Integration to suit your organisation

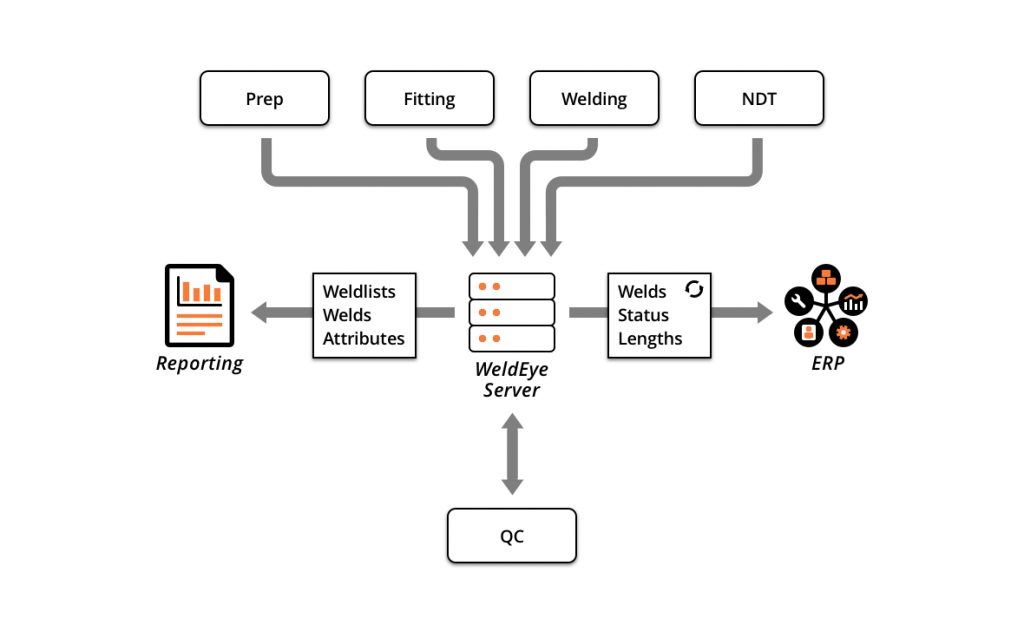

The goal for us is to provide a set of technologies and interfaces that allow our WeldEye welding software to be integrated with other systems efficiently with minimal effort and maximum pay-back. The integration allows other applications to send information to and retrieve information from WeldEye and vice a versa. We would be happy to run through a demonstration of the WeldEye welding management software, you can contact us to set one up.

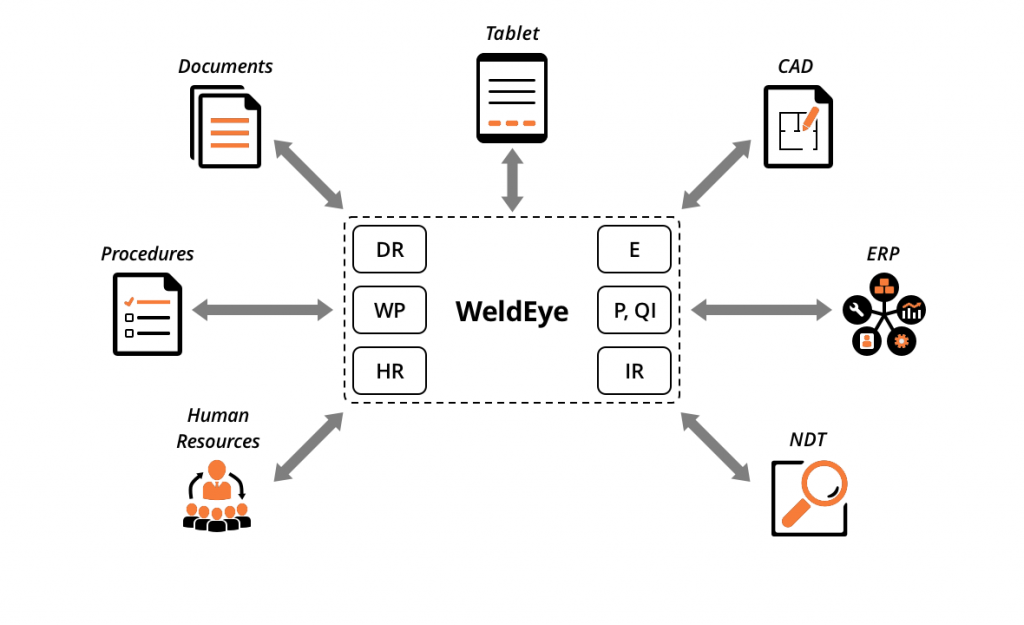

The WeldEye® Welding Management System can also be integrated into existing systems like ERP,

CAD and/or HR systems, so that it becomes a natural part of the complete production chain. This will provide the fabricator management with a true end-to-end solution covering all disciplines needed to optimise the production. You can also download the WEIK white paper in full here.

WeldEye Integration kit (WEIK)

The full WeldEye Integration Kit (WEIK) consists of six modules:

Web services

This is the preferred choice. Both directly (i.e. web service calls from one application to another) and indirectly (i.e. via the Enterprise Service Bus (ESB)) web service calls can be used. The latter allows (amongst other) the application to pick up the files, convert them and then send them on to the web services in WeldEye®.

- Standardised

- Easy to build on our existing business logic

- Easy to develop and maintain in our architecture (JEE / Java)

- Abstraction of internal structures (hide internals)

Web services usually connect through https (SSL) secure connection to provide confidentiality. The SSL strength may vary depending on what kind of certificate is used in the connection.

Our current APIs are SOAP APIs. All requests to web services must be authenticated by a user principal and all normal WeldEye access controls apply to that principal.

RESTFul API

JWT

RESTFul APIs are becoming more common in todays web environment and WeldEye also provide som RESTFul APIs. RESTFul APIs started out as set of best-practices, and while some standardisation has occurred, it is not as well defined as SOAP APIs. If you required things like schema validation we recommend to use Web Service/SOAP.

- Not as strictly defined as SOAP – best practices used where applicable

- Easy to build on our existing business logic

- Easy to develop and maintain in our architecture (JEE / Java)

- Abstraction of internal structures (hide internals)

All requests to RESTFul APIs must be authenticated by a user principal and all normal WeldEye access controls apply to that principal

JSON Web Token is an access token that is used to assert some claims. This token is verified by signature using public and private keys. JWT is based on a RFC standard, but the signature algorithm may vary between implementations.

JWT can be used to authorize a request to WeldEye, but does not provide any benefit compared to a Basic HTTP authentication.

To use JWT with WeldEye, WeldEye must know the public key to verify the JWT with and provide user identification within the claim.

Database link

Manual file upload

This is used to make reports in other applications that require data from WeldEye®.

- Very fast data extraction

- Well-defined interface for reporting tools

- No guarantee on database changes in new WeldEye version

Supplied to allow easy data transfer from legacy systems. This is more suitable for migrations than integrations.

- WEIK Documents

- WEIK Procedures

- WEIK Human Resources

- WEIK CAD

- WEIK ERP

- WEIK NDT

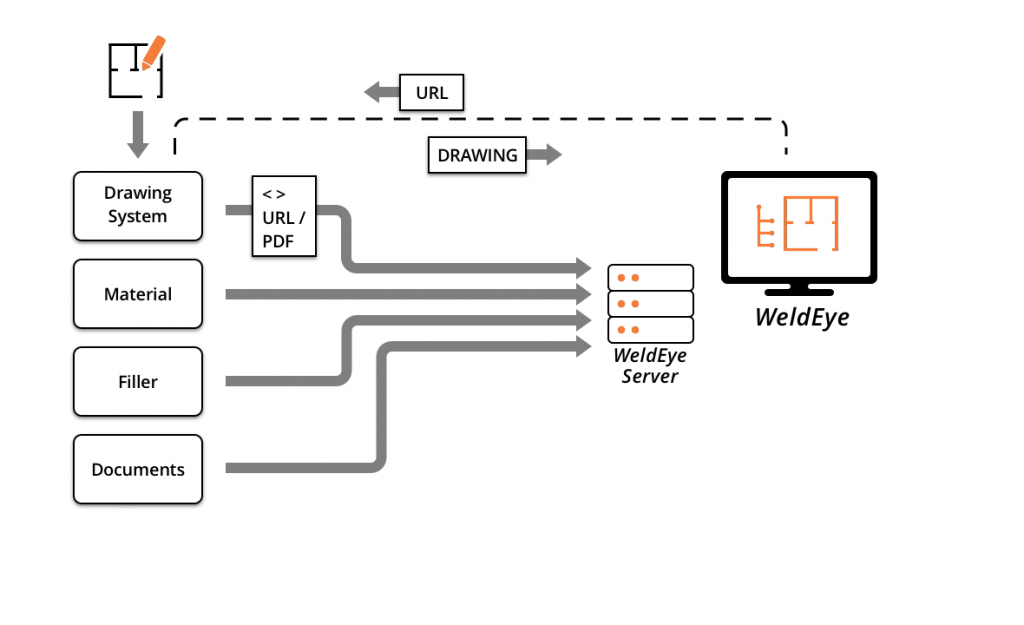

Module: Documents

WEIK Documents handles integrations with documentation systems and integrates with the Document Register module in WeldEye™. It works with drawings, material certificates and filler material certificates as well as general documents (for instance general welding procedures and standards).

Typical use is to update WeldEye™ with documents (for instance drawings) from documents handling systems which enable users to use these documents directly in WeldEye™ for drop-down, sorting and including as part of as-built documentation.

Module: Procedures

WEIK Procedures integrates with the Procedures module in WeldEye™ and handles Welding Procedures (WPS), Brazing Procedures (BPS) and NDT Procedures.

Typical use is to get information from procedures maintained and managed in WeldEye™ into other systems which can use this, for instance lists of WPS used in projects.

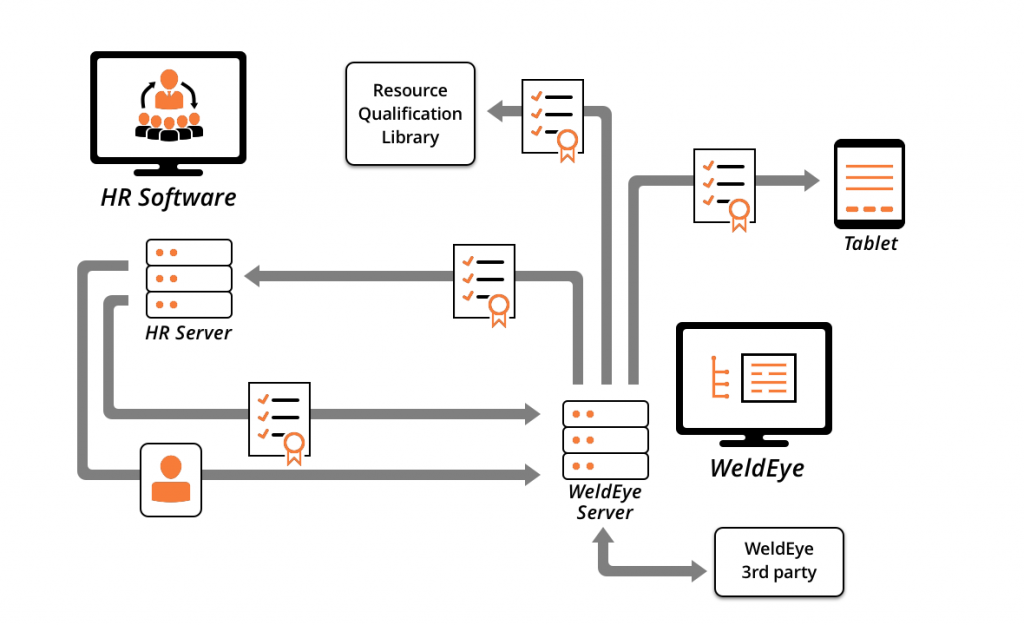

Module: Human Resources

WEIK HR (Human Resources) integrates with the Personnel and Qualifications modules in WeldEye™. This WEIK module can be used to update WeldEye™ with information about personnel from the company’s own HR system. It can also be used to get information about personnel and, in particular, their qualifications stored in WeldEye™.

WeldEye™ has a separate integration module called WeldEye™ PQ Integration which keeps Personnel information and Qualifications (certificates) synchronized between a Certificate (3rd Party) Body and a Fabricator. This module is not included in WEIK.

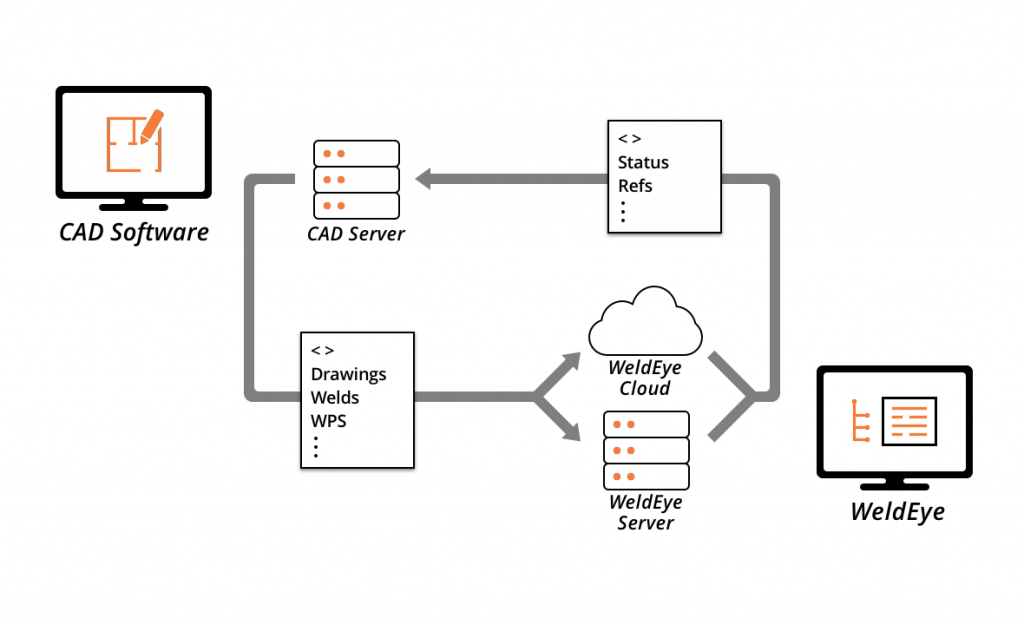

Module: CAD

WEIK CAD (Computer Aided Design) integrates with Engineering of WeldEye™ Welding Management. It can be used to create the Product Breakdown Structure (PBS), add Weld Lists, and populate Weld Lists with welds.

Typically this is used to transfer data and metadata from the product model in a CAD system into Weld Lists. If the model in the design system holds all the relevant information, the Engineering step in WeldEye™ can be automated and will not require any user input.

Services:

- Create PBS elements (Serial no., Section, Lines, and Drawings)

- Create Weld Lists

- Populate Weld Lists with welds

Module: ERP

WEIK ERP (Enterprise Resource Planning) integrates with the general work flow in WeldEye™ Welding Management. It can be used to report and sign off steps as welds are fitted, welded, inspected, etc. It can also be set up to send progress information from WeldEye™ to an external system.

Services:

- Create projects and get project information

- Report various steps, such as

- Fitting

- Welding (Production)

- Inspection

- Receive progress and status information from WeldEye at reporting steps (i.e., the information is sent from WeldEye to an external system)

Module: NDT

WEIK NDT (Non Destructive Testing) is used to handle inspection (primarily NDT) reporting and NDT reports and integrates with the Inspection Report module as well as the Quality Inspection (NDT) step in Welding Management.

Services:

- Report inspection

WeldEye Management by Weldindustry

Weldindustry AS, Drammensveien 288,

0283 Oslo, NORWAY

Org. no. 983 448 224