About weldeye

WeldEye Management Software

Benefits & Possibilities

A universal solution for managing your Welding Production

WeldEye Welding Management focuses on streamlining your welding documentation flow, improving quality and efficiency, giving you all data and statuses in real time, as well as tailoring your documentation requirements based on relevant industry standards. By digitalising all documentation processes, WeldEye is able to save you time and money in all welding projects, as well as improving the quality and outcome of your welding projects.

We like to think of WeldEye as the ERP system of the Welding World.

Book a free online demonstration, send our solutions sales manager, Silje Holvik, an email with some information about your company and your contact details and she will get in touch to arrange a demonstration.

Here are some of the benefits and possibilities you get with WeldEye:

WELDEYE FOR MANAGEMENT

Nearly all areas in today’s welding production environment, from planning, engineering and construction have for a long time been under constant evaluation for improvements. Just imaging building a crane, oil pipe, platform, windmill or nuclear power plant planned on paper and not using 3D modelling tools. Possible, but a highly inefficient way to do so. Now, it is also time for the support systems for welding production to be the next area where fabricators can improve efficiency by controlling the processes and structuring the documentation.

Here are some of the ways WeldEye can improve your welding projects:

Manage and share your workload

With WeldEye you can concentrate the work in the area where it belongs, and avoid your most valuable assets being forced to run around the manufacturing halls in order to collect data. Let the welding data come to them instead.

Let your Welders sign off completion of welds, let the NDT controller sign off on his reports, let the welding foreman issue work orders and let management see the big picture, all within the same welding software.

Management dashboard

A convenient and easy way of viewing the most important data in one screenshot.

This screen is filled with configurable Widgets giving you status reports on number of welds per welder, defect rates, certificates up for renewal, expired certificates and more.

Set the dashboard up as your login screen, and configure with the data needed for your welding projects.

Improve quality

WeldEye® Welding Management System covers all steps in welding production and all the data is handled by one system, a unique overview during the complete projects are available for the users. Who is doing what when and where and according to which procedure is traced. You can read in more detail about the Personnel and Qualifications module here. The result from testing and repair is also in the same system. This means that the output from the system is also unique. In addition to following the production process and status, the personnel, the welders and their certificates, there are additional statistical functions included, all to give you the best welding management tool possible.

Increase your competitive advantage

Deliver a complete, as-specified, documentation package according to your customers´ needs on project closing date, leaving you ready to take on new projects. Further details on the Document Register module can be seen here.

Deliver accurate and timely status reports on the process of your welding project, with all data being logged in real time. Digitise your welding process with WeldEye and take your planning, tracking and reporting to the next level.

Free up valuable resources and take on more profitable projects!

weldeye - time / cost savings

WeldEye saves your organisation time and money by digitising all welding management processes, eliminating time consuming duplicate and manual registrations, inefficient filing systems in inadequate programs like word or excel, with hardly any traceability, limited search options, no links to standards or actual project status in real time, to mention a few.

Some time and cost saving functionalities of our welding software include:

- Intelligent drop down menus – only showing relevant options based on a set of filters (override function available)

- Autofill-in functions – avoid having to register the same data twice.

- Quick-links to relevant documents – get access to the information you need where you need it

- Certificate prolongation tool – selects relevant welding jobs for your welders certificate renewal

- Import/export functions

- Automatic Status reports to send to management

- Reject rate reporting tool – with full control of your reject levels you can avoid costly over-testing

- Time saving integrations for quick and automated dataflow

These are just some of the functionalities available with our welding management system, you can view more in-depth data on how digitising your welding production with WeldEye works on our modules page.

weldeye - cloud or local

Cloud solution

Benefits:

- Easy access through Internet

- Free and automatic software updates

- No server needed and costs saved

- Monthly user fees invoiced according to actual use, giving your organisation much needed flexibility

Our welding software can be deployed on standard IT platforms and accessed from any PC (with browser) and different devices (PDAs, mobile phones, etc).

Local network solution

Benefits:

- Provides global access

- Handles multi-site accessibility

- Possibility for customisations

WeldEye® Welding Management local installation is installed on your own IT infrastructure.

weldeye - universal solution

WeldEye® Welding Management is a universal solution that will work with any company that has a welding operation, but is designed especially for project based welding, and companies who have to adhere to stringent standards and requirements.

Typical WeldEye Management industries are:

- Oil and Gas

- Offshore

- Defence

- Energy (nuclear, power plants, piping)

The WeldEye system is dynamic, flexible and scalable to fit any organisation irrespective of size and complexity. It supports international standards, multiple languages and multiple site installations.

Overall, WeldEye® Welding Management users have experienced the benefits of reduced rejections, reduced costs, better control of welding projects and an easier method to track down the welding issues in cases of welding related problems.

Make the best strategic decision for the future now and include the WeldEye program in your organisation.

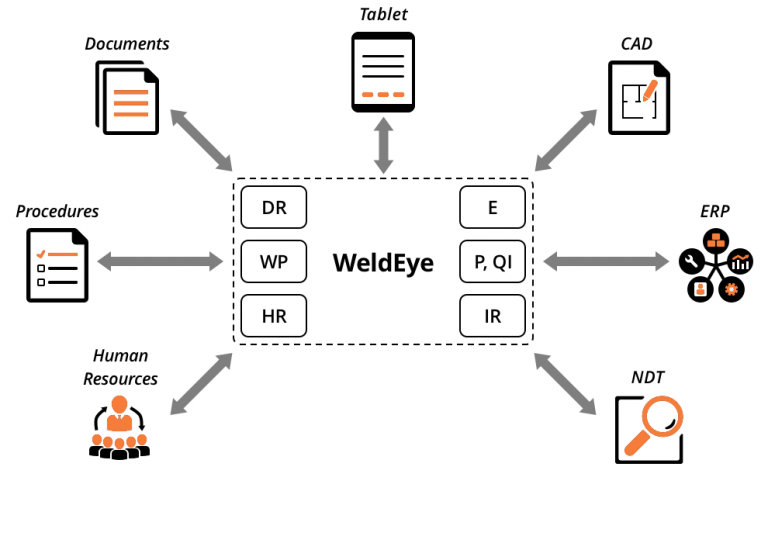

weldeye - integration kit

The goal for us is to provide a set of technologies and interfaces that allow WeldEye® Welding Management software to be integrated with other systems efficiently with minimal effort and maximum pay-back.

The integration allows other applications to send information to and retrieve information from WeldEye and vice-versa.

You can read in more detail about integrating our welding software here.

WeldEye® Welding Management Integration kit (WEIK)

weldeye - flexible and configurable

WeldEye is a flexible and configurable system that can be set up according to most welding projects’ needs and requirements. Here are some of the ways you can configure WeldEye for your organisations needs:

- Set up your production steps according to your needs for each project. Which steps you want to go through to register your welds, which fields should be mandatory, optional or not included, which signatures would be needed etc. All unnecessary steps can be hidden.

- Set up your NDT matrix. Include the reports you use for each project acceding to your standards and customer requirements. Readjust test requirements according to the actual test results.

- Available in multiple languages.

- Flexible product breakdown structure setup, including renaming options for an easier introduction to your company.

- Set up the dashboard to convey the information you need access to quickly and easily.

- Use the WeldEye software on your PC, portable handheld device in the production hall, or as a report through pdf´s.

- Add your company logo to WeldEye.

- Create your own sketches using one of WeldEye’s two sketch tools or upload existing files.

- Have your inspectors sign off inspections directly in WeldEye, or add external reports.

You can read more about the modules available in WeldEye here.

weldeye - improve quality

WeldEye Welding Management can help you improve quality by specified access control, intelligent input checks, overall traceability, access to audit trails on welds etc. as well as ensure projects comply with specified standards and requirements.

With WeldEye® Welding Management you control and manage what information can be inserted, extracted, signed and revoked.

The WeldEye® Welding Management System can identify all welds in any structure, when a weld was performed, by whom and with which WPS, material ID it was produced.

The application provides full traceability of all welds and all activities on these welds during the whole production process.

WeldEye provides detailed reports on welding, testing and repair, welder status and more.

weldeye - ensure compliance

Welding is one of the most stringent and controlled production environments. Documenting compliance to welding procedures, welders, welder certificates, qualifications, materials, NDT testing, weld repair handling, etc. is resource demanding and needs to be streamlined in order to be cost effective.

Despite comprehensive technological development in the last few years, it is still quite common to handle parts of welding documentation by using manual or in-house built non-commercial solutions to cover the requirements. Welding engineers and managers are under constant pressure to improve the quality of welds produced and to document compliance to strict requirements.

WeldEye® Welding Management offers:

- Control and traceability in the welding production process

- Better quality, more accurate, as-built documentation

- Quicker decisions based on correct information

- Real-time status on executed and outstanding weld production

- Complete project status for management

- Documented fulfilment of customer requirements

- Updated requirements from international standards

WeldEye Management by Weldindustry

Weldindustry AS, Drammensveien 288,

0283 Oslo, NORWAY

Org. no. 983 448 224