Manage your weld

projects digitally

Want to manage your entire weld project digitally?

We at Weldindustry have been developing Welding management software for over 20 years, and can now offer a solution that is flexible, configurable and extensive.

The idea is to provide our customers with an end-to-end solution that takes into account the entire weld project.

From planning to final documentation...

Our definition of a welding management system, here at Weldindustry, is “a software program that improves your efficiency, profit, control and quality in all stages of your welding projects – from engineering through fabrication, testing, and reporting to final documentation.”

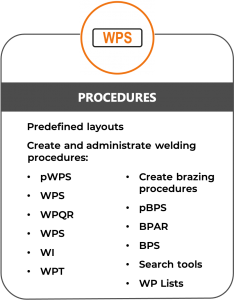

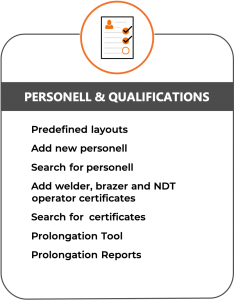

It should, in our opinion, include status reports, traceability records, management of WPS, welders and certificates, NDT reporting with access and input control, and so much more, all to ensure you work efficiently and with less errors creeping in.

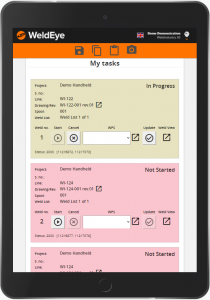

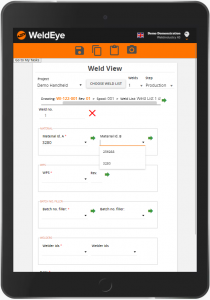

Welder's WeldEye

Shopfloor functionalities and handheld

To further save you time and paperwork you can also use our shopfloor functionalities, where welders can have a specified user access, and access the system through a portable tablet.

With Welder’s WeldEye they can:

- Choose weld by scanning barcode or choose from dropdown menu

- Access drawing relating to the weld in progress

- Choose procedure by scanning barcode or choose from dropdown menu (as specified in project)

- Choose material by scanning barcode or choose from dropdown menu (as specified in project)

- Choose filler by scanning barcode or choose from dropdown menu (as specified in project)

- Report finished weld, with your welder’s ID, time and date.

All the date reported on tablet is instantly transferred to the Welding management system, giving you real-time data on the progress of all welds and overall project status.

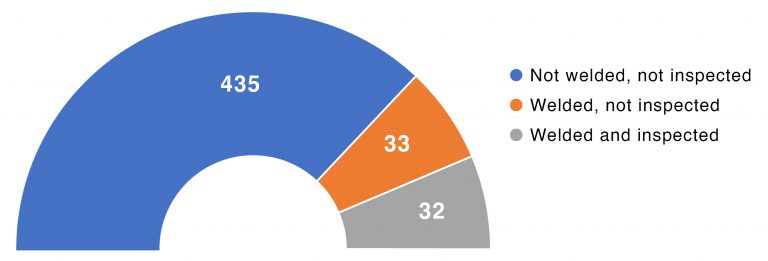

Dashboards for easy overview!

Our WeldEye dashboards can be set up for each user, according to their needs and access rights.

Some of the widgets you can choose from are:

- Weld Progress

- Certificate status – number of active certificates oe certificates that need prolongation etc.

- Defect rates per welder

- Defect rates per inspection method

- My tasks

- Welds per welder

- Defect categories

MAJOR WeldEye timesavers:

No more running around offices and production halls gathering data on paper, entering the same data multiple times

- Drop-down menus for data already registered in the system – less need to type and correct!

- Hyperlinks to quickly go to relevant information

- The all-important Status overview at your fingertips

- Shopfloor functionalities for welders to input their weld data

- Advanced search functions – to get you exactly what you are looking for, no more no less.

- Print tool – Pick and choose what you want included in the print package and press – PRINT

- Real time data input – and output – whenever it is needed

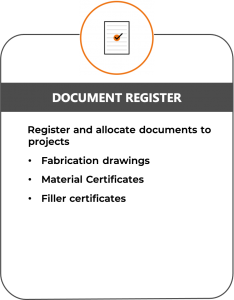

- All the documentation you need in ONE system

Need we say more?

Other useful functionalities include:

- E-mail notifications

- Status reports on welding , testing and repair per project

- Status reports on remaining welds

- Welder status

- WPS status reports

- Specified access control

- Intelligent input checks

- Overall traceability

- Access to audit trails on welds

- Import/export functions

Integrations

And of course we offer Integration possibilities to further increase efficiency and control.

To learn more about how we can set up the system to match your needs, book a demo or contact us by mail or phone.

You can also follow us on LinkedIn to get more tips and tricks on managing your welding project, and see all the new updates from Weldindustry.

WeldEye Management by Weldindustry

Weldindustry AS, Lysaker Torg,

3rd floor, 1366 Lysaker, NORWAY

Org. no. 983 448 224